What are they?

First, they in no way involve the use of unsightly glasses. Three Dimensional printers or 3-D printers, are just like the printers we all know and love, except instead of printing an image of a thing, it prints the thing itself. That, and they may look a tad different from your desk jet. 3-D printers can print products almost without regard to geometrical limitations, through subtraction and or fusing methodologies, providing a designer or inventor incredible flexibility, freedom, and speed in sketching an item having said item in hand. Excitingly, while 3-D printers have been around for quite a while, they have become increasingly affordable, efficient, and accurate.

Who makes them?

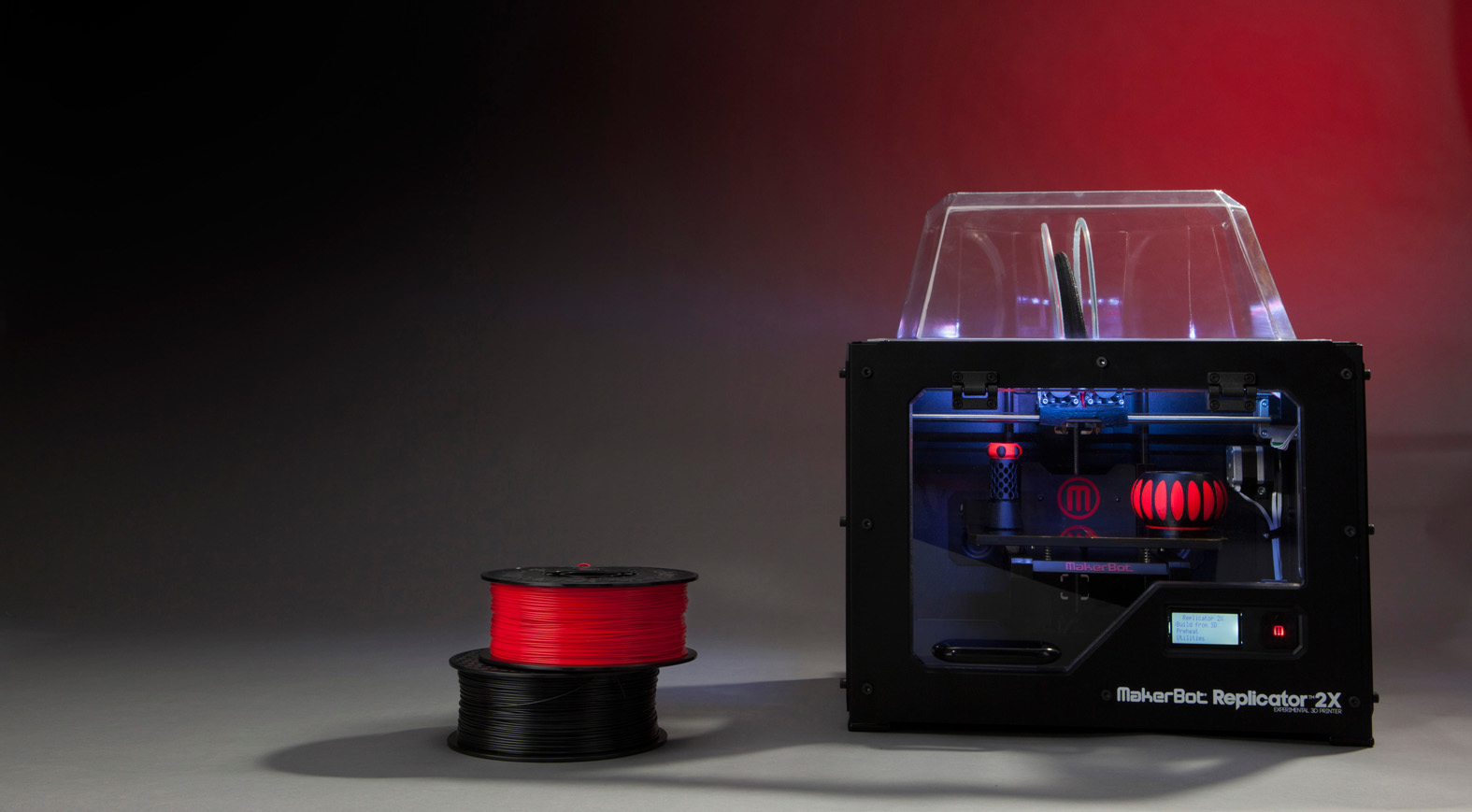

Many companies make 3-D printers but there are a few big players worth noting for the sheer scale of their operation, and then the startups or Kickstarter types, that are most interesting for their potential of bringing 3-D printing to the masses. Stratasys and 3-D Systems are bigger companies, who have been dominating the 3-D printing market through mergers and acquisitions (Stratasys recently acquired MakerBot)[i], or through powerful connections with consumer facing corporations like Staples. With the larger companies and their rate of acquisition, it’s hard to keep track, by the time you read this they could have all melded into one giant thousand-headed-beast. However, your attention really should be directed to organizations or companies who stand to make 3-D printing as normal as HP and Cannon did with their with inkjet desktop printers. In particular, the ground-work laying RepRap, the seemingly less compromising FormLabs Form 1, and the affordable Buccaneer, and Makible printers will likely be disruptors in the 3-D printing space.

So, just what can they print?

3-D printers have traditionally been used for rapid prototyping. That is, they were mostly used to model products throughout development stages and not typically used to build final consumer products. This is still a large part of the behemoth 3-D printer company’s business. The more expensive standalone 3-D printers have been used to make one off parts, but are simply not affordable enough to be found in the average garage. For example, Jay Leno’s Garage, hardly the average garage, used a Dimension printer, and a scanner to scan and print an old car part. Now-a-days, desktop 3-D printers even with wildly varying levels of resolution[ii] (complexity and fine-detail ability) facilitate home-production-lines and have been used to print anything from toy dinosaurs, to iPhone cases. Additionally, desktop 3-D printing has made rapid prototyping much more affordable and accessible, even if most are not able to replace an actual factory production line. Organizations with more resources are also harnessing the power of 3-D Printing technology for some really fascinating projects.

Recently, NASA awarded a research grant to Systems and Materials Research Consultancy (SMRC) to explore the possibility of 3-D printers making food in space. In SMRC’s proposal they plan on printing food using a 3-D printer, while using an inkjet to add flavor and nutrients. This is all a part of NASA’s efforts to make improvements in life-support systems, such as supplying food to crew on lengthy deep-space missions. NASA plans to send a human mission to Mars by the 2030s[iii].

Organovo, a human tissue developer, is using 3-D printing to print human tissue for use in medical labs. They eventually hope to create a “potential new source of tissues for surgery and transplant medicine.” The outfit just recently offered up 9 million shares, from which they expect to raise $37.7 million and plan on using the funds for research and development, and the commercialization of products, amongst other things.

Recently, A 25-year-old Texas law student and group printed and fired a plastic handgun (save the metal firing pin), made with a Stratasys Dimension printer. That law student and group are also focused on creating from a 3-D printer, lower receivers (the most complex part, and part designated to be a firearm) for AR-15 semi-automatic rifles. Simultaneously, incredible and scary to be sure.

Whatever the public sentiment about what 3-D printers can make, whether it be petrifying or impressive to print human tissue, a gun, or pizza, most people would agree that the most interesting thing a 3-D printer has printed thus far, has been itself. RepRap deserves a lot of credit for having been the facilitator of persons making the dive into 3-D printing. The RepRap printer project is a true disrupter for its machines ability to self-replicate, or at least partially self-replicate. You're probably immediately wondering how long we have until full replication and RepRaps take over the world and hold us at laser gunpoint. Not long friends. The team at RepRap expect the machines to be at 100% self replication in the not too distant future. Complications such as the metal components of the machine have been one of the more challenging aspects in achieving total self-replication. Consider for a moment the ability to print another printer after purchasing one, then almost exponentially printing new printers. That is powerful.

Most 3-D printers take some base plastic and print only plastic materials. There are some printers that can print from metal; some that take a proprietary resin or mix, and others that can print from some other interesting base, like chocolate. One company, Filabot, sells a machine that recycles plastic into filament for 3-D printers.

Without question, eventually 3-D printers will be able to manipulate several different kinds of complex materials. That's when things will really get interesting. Perhaps even more exciting, will be the establishment of a universal kind of Higgs Bosson-ish base material from which a plethora of other materials such as plastics, metals or glass could be built with proper agitation. At this stage 3-D printers will be able to construct incredibly complex products.

Simply, I put the mark of singularity for 3-D printers, where a household desktop 3-D printer is able to print a product with a functioning circuit.

How will it be when 3-D printers truly become mainstream?

At singularity intellectual property will be all that matters. Imagine shopping for your needs or wants at sort of merger between Amazon.com and Makerbot's Thingiverse. We will simply purchase intellectual property in the form of schematics we never see accompanied by certain rights, or those so inclined will fire up an average consumer simplified version of AutoCAD or Photoshop and print away.

No doubt, this will pose similar troubles to those faced by the entertainment and software industry with piracy. With a little ingenuity who will stop me from taking my friend’s iPhone case schematic file and printing a case or two for myself? For this reason, 3-D Printers may be highly regulated, perhaps incapable of functioning (if not hacked), without phoning home or being directly registered to its user, or including a traceable mark and license for each print, linked to some massive cloud based receipt or licensing service. Companies and owners of intellectual property will want some presumption of liability attached where a user is not able to show compensation for some product printed from 3-D printer.

The bright side will of course be choice. With the barrier to entry for manufacturing removed, consumers will be exposed to many more products than they would have otherwise been, and it will be easy for an individual or micro-organization to design and bring products to market. It is currently quite difficult for a small operation to have a product built in the United States. For example, around 2007 when I attempted to realize a product design, I was told that the mold alone for the prototype would cost over $10,000. Mind you, this was a product with no moving parts, and essentially amounted to a 4” x 3” x .35” piece of plastic printed in a particular shape. Based on what I imagine was the shock and horror on my face, I was later told that perhaps the manufacturer could simply prototype and order the product from China, thereby saving me a significant portion of lint in my pocket. This was only 6 years ago, yet today I can purchase a decent desktop 3-D printer for less than a third of my quote, thus removing the need to have a prototype made outside the U.S.[iv].

Ultimately, a world where a 3-D printer is as commonplace as an HP all-in-one is a good thing for you and I despite some negative implications.

How close are we to HP selling you that all-in-one "3-D printer/scanner/fax" for $99.00?

Even with all the buzz surrounding 3-D printers today, in large part because of Wall Street, seemingly 3-D printers are the things of sci-fi movies and not nearly on the cusp of truly becoming mainstream. However, that notion is much more less sound than it would appear. Microsoft’s latest version of Windows 8.1 includes native support for 3-D printing. Also, Makerbot’s Replicator 2 and accessories, are sold on Microsoft’s online store. Anyway you slice it, this is a huge vote of confidence from the company that builds the worlds most popular operating system. Further, Staples now sells Cubify's Cube 3-D printer and accessories online and have placed some on display in its stores.

It may not be next year, but 3-D printers are breaking away from being a novelty item. Soon enough you will have one on your desktop and intellectual property will be all that matters.

[i] (Cooley Advises Global 3-D Printing Giant Stratasys on Its $403 Million Acquisition of MakerBot, Technology Digital, July 4, 2013)

Cooley LLP announced today [July 3, 2013] that it acted as US counsel, along with Israeli counsel, Meitar, to Stratasys Ltd. on its $403 million acquisition of MakerBot. Stratasys manufactures 3-D printers and materials that create prototypes and manufactured goods directly from 3-D CAD (Computer Aided Design) files or other 3-D content. MakerBot, the leader in the desktop 3-D printing industry, will operate as a separate subsidiary of Stratasys, maintaining its own identity, products and go-to-market strategy. Subject to customary approvals, the merger is expected to be completed during the third quarter of 2013.

[ii] (3-D Systems, 3-D Printer Buyer’s Guide, www.3-Dsystems.com)

One of the most confusing metrics provided on 3-D printers is resolution and should be used with caution. Resolution may be stated in dots per inch (DPI), Z-layer thickness, pixel size, beam spot size, and bead diameter just to name a few. [However] the best comparisons are visual inspection of parts produced on different technologies. Look for razor sharp edge and corner definition, minimum feature size, sidewall quality and surface smoothness. Use of a digital microscope may be helpful when examining parts as these inexpensive devices can magnify and photograph small features for comparison.

[iii] (Indira Kannan, The food printer, Business Standard, June 15, 2013 Saturday)

NASA's grant is part of its Small Business Innovation Research programme. The Phase 1 contract is worth $125,000 for the six-month study. "As NASA ventures farther into space, whether redirecting an asteroid or sending astronauts to Mars, the agency will need to make improvements in life-support systems, including how to feed the crew during those long deep-space missions," says David Steitz, a NASA spokesman at the agency's Washington, DC, headquarters. NASA has said it plans to capture and relocate an asteroid by 2025 and send a human mission to Mars by the 2030s.

The digital media outlet, Quartz, described the company's prototype pizza printer that prints a layer of dough, which is baked at the same time as it is printed by a heated plate at the bottom of the printer. Next it lays down a tomato base and is finally topped with a protein layer. It can thus produce a pizza that is the closest the astronauts can get to a real one in taste and feel 400 km in space.

…In its proposal, SMRC offered to build a complete nutritional system using 3-D printing and inkjet technologies. The 3-D printer would deliver macronutrients such as starch, protein and fat in a variety of shapes and textures. If that sounds unappetising, the inkjet will add micronutrients, flavour and smell to the products. SMRC plans to team up with the food science programme at North Carolina State University and the multinational company International Flavors & Fragrances, Inc. to develop its recipes.

…According to SMRC's proposed design, the macronutrient stocks "will be combined with water or oil according to a digital recipe" at the print head. Flavours and texture modifiers can be added at this stage, and the mixture is then blended and extruded into the desired shape. SMRC also sees several potential non-space related commercial applications for its food printer. Among them is their use in military missions, aircraft carriers and submarines.

[iv] (John Koten, Unleashing Innovation (A Special Report) --- A Revolution In the Making: Digital technology is transforming manufacturing, making it leaner and smarter, and raising the prospect of an American industrial renaissance, The Wall Street Journal, June 11, 2013 Tuesday)

…technological advances now allow manufacturers to invent new ways of fabricating things that represent an extreme departure from the classic production-line model. By far the most significant of these steps forward is additive manufacturing -- a process of making a three-dimensional object of virtually any shape from a digital model.

…Still, manufacturers will have to navigate big new challenges in this era, too. For one thing, because additive manufacturing works from digital models of objects, companies are much more vulnerable to intellectual-property theft -- the same way that easily copied music and movies have shaken the entertainment business.

Last year, Boston Consulting Group published a report predicting that as much as 30% of America's exports from China could be domestically produced by 2020. President Obama gave a nod to this hope in his State of the Union address in February when he said that the popular additive-manufacturing technique called 3-D printing "has the potential to revolutionize the way we make just about everything."